Steel Square Tube/Pipe Making Machine Forming Machinery

………………………………………………………………………………………………………………………………………………

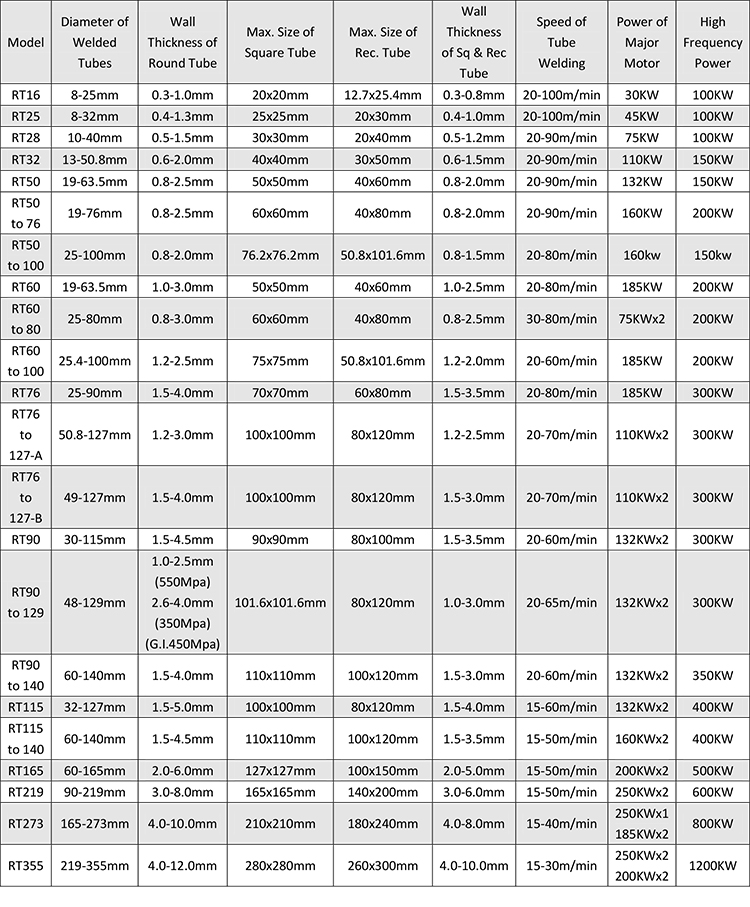

Shang hai Sino Power offers almost 30 standard models, covering range from 3/8’’(8mm) up to 10’’(273mm) diameter (corresponding square & rectangular tubes) and wall thickness from 0.3mm up to 12.7mm, also accept customized machines.

Suitable material: Carbon Steel Coil , Galvanized Steel Coil

Steel Square Tube/Pipe Making Machine Forming Machinery Application

………………………………………………………………………………………………………………………………………………

1. Water pipe

2. Heating pipe

3. Low-pressure process pipeline

4. Low pressure fire fighting pipeline

5. Sewage Pipes

6.Steel Scaffolding Pipe

7. Wire and cable protection pipe

8.Structural support Steel Pipe

9. Industrial Steel Pipes

10. Decoration Pipe

11.Oil & Gas Pipes

Steel Square Tube/Pipe Making Machine Forming Machinery Flow

………………………………………………………………………………………………………………………………………………

Slit Coil ---- Un-Coiler ---- Shearing And Butter Welder ---- Storage/ Accumulator ---- Forming ---- Welding ---- Cooling ---- Sizing ---- Cutting Saw ---- Run Out Table ---- Finishing ---- Pipe Collecting and Packaging

Steel Square

Tube/Pipe Making Machine Forming

Machinery Process

………………………………………………………………………………………………………………………………………………

(1) Raw material preparation – forge piece: inconel

(2) Semi-finishing; Numerical control cutting machining

(3) Numerical control finishing machining

(4) Product inspection – dimensions, form and position tolerance

(5) Product inspection – hardness

(6) Customer inspection

(7) Finished-parts storage – shipshape

(8) Packing

Steel Square

Tube/Pipe Making Machine Forming Machinery Optional

Models

………………………………………………………………………………………………………………………………………………

1. LCL Loading Packaging: Steel pallet and plywood case.

2. FCL Loading Packaging: Steel pallet with plastic film.

3.Shipping: by sea

Our services

…………………………………………………………………………………………………………………………………………………………………………………

Provide Pre-sales Consultant & On-purchase service 8 hr × 6 days per week

1. Reply within 24 hours

2. Provide relevant product information

3. Answer questions if request

4. Give technical suggestion

Provide After-sales service 24hr × 7days per week

1.Test the machine before shipment

2. Provide technical guidance relate to use the machine

3. Supply one-year warranty period for the machine

4.Provide the spare parts at cost price after warranty period

5. Collect the feedback for the machine working

6. Provide long-term technical assistance.

Contact: Steven Ma

Phone: 86 18321624120

Tel: 86 021 58307665

Email: stevenma@shsinopower.com

Add: Pudong Shanghai ,China