Steel Coil Slitting Machine Manufacturers-Sino Power Company

What elements decide the slitting machine line price and structure?

Normally speaking, the slitting blades are designed depending on the job required. The four critical determinants of the blade configuration include:

• The material thickness and the material hardness

• The type of material to be slit and how many pieces you want to slit

• The tolerances that must be held while slitting

• The working speed of the metal slitting line

Slitting line may be designed just as coil slitters, or just as cutting shears, but many metal fabrication machines can do both.

Slitting Line , called slitting machine or longitudinal cutting line, is used to uncoiling, slitting, recoiling the steel rolls into demand width steels. It can be applied to process the cold or hot rolled steel coil, Silicon steel coils, tinplate coils, Stainless steel and color coated steels.

1.Function: It is used to the longitudinal cutting for the steel coils and rewinding the slit strips into coils.

2.Advantages: Convenient to operate, high cutting precision and utilization factor of the material, adopts the infinitive speed.

3.Structure: Compose of Decoiler, feeding device, slitting machine, recoiler (Rewinding) machine.

4.Material can be processed: galvanized steel, stainless steel tinplate, silicon steel ,copper and aluminum, etc.

5.lndustries can be applied to: steel factory, transformer, electrical motor, electrical equipment, car, building materials, door, packaging industries.

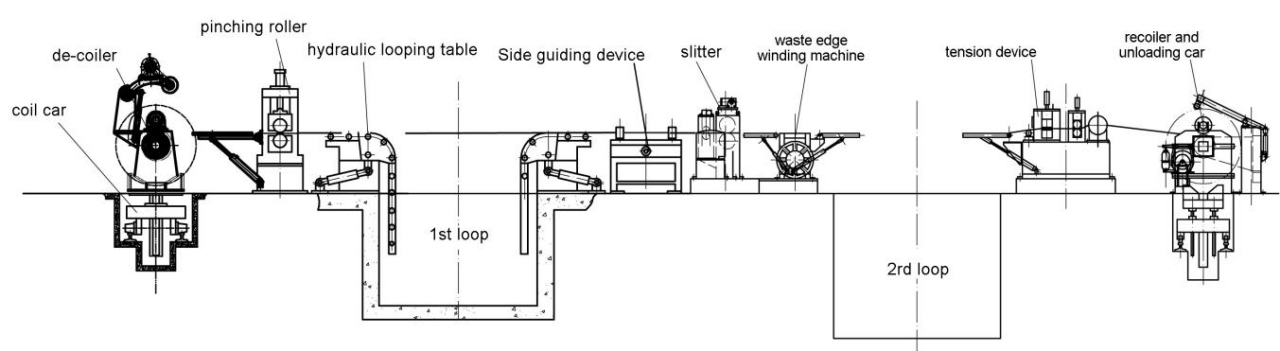

Slitting machine line working process:

Hydraulic coil car→ Hydraulic decoiler→ Hydraulic feeding guide device→ Pinching roller → Hydraulic storage lifting bridge → side guiding device→ slitter machine→ waste edge collecting machine→hydrautic storage lifting bridge hydraulic tension device→ recoiler machine→ hydraulic unloading car

.jpg)

.jpg)

.jpg)

Slitting machine line Inspection & Warranty:

For the slitting line, we have strictly quality control system. If the slitting line quality is not good, it will affect the accuracy of silted coil width. If the coil width is not accurate, we can not use them together with the welded pipe machine.

Here are some parameters for your reference about how we control the quality of slitting line.

|

Model |

SP0.2-12×500/2000mm |

|

Coil Material |

δs≤230N/mm2,Cold-rolled Coil,Hot-rolled Coil,Stainless Coil,Galvanized Coil |

|

Coil Thickness |

0.2~12mm |

|

Coil Width |

100~2000mm |

|

Coil Weight |

5~30T |

|

Coil I.D |

φ508mm 608mm |

|

Coil O.D |

≤φ1600mm-2000mm |

|

Strip Width |

≥25mm |

|

Number of Strip |

5~25 |

|

Slitting Accuracy |

±0.1mm |

|

Line Speed |

0~120m/min |

|

Electrical Control System |

PLC Automatic control |

Slitting machine line equipment & product

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Contact: Steven Ma

Phone: 86 18321624120

Tel: 86 021 58307665

Email: stevenma@shsinopower.com

Add: Pudong Shanghai ,China